We developed our large format 3D printing technology with end-user needs in mind, after years of collecting experience on producing parts for clients.

We aim to ensure production quality and continuity for the most advanced industrial applications.

Heron is a modular, integrated hardware, software, and automation platform, all in one solution to enhance the flexibility, efficiency, and sustainability of your manufacturing processes, ensuring control of the production cycle, minimizing risks and downtimes.

As one provider, Caracol delivers quicker innovation, higher customization, and prompt and reliable support.

Heron AM meets the highest standards for production, these systems are the first of their kind to be certified to meet the most demanding industrial requirements and process quality criteria.

We aim to always deliver precise and reliable technology, supported through an extensive set of services to help you leverage the full potential of your machines.

Modularly configure Heron AM, to fit your industrial manufacturing needs with no limits in scale, shape, and material.

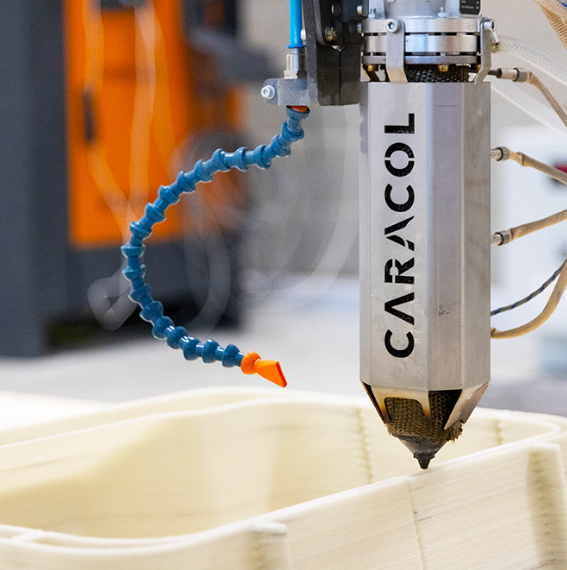

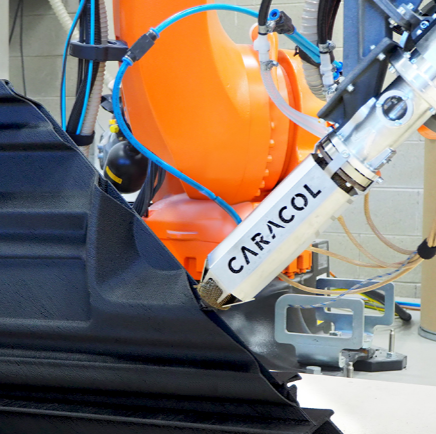

Caracol’s extruders process composite fiber-reinforced thermoplastic pellets. According to the manufacturing needs different models are available, assuring cost-effective, performance, and quality.

The High Accuracy (HA) extruder is lightweight and compact to achieve agility, quality finishing, and precision. The High Versatility (HV) extruder flexibly adapts to diverse industrial needs and a broad range of applications.

The High Flow (HF) extruder drastically reduces print times. With its robust structure, high throughput, and temperatures, it processes an extensive range of materials maintaining high print quality and efficient deposition.

Lightweight, compact head for agile and detailed printing. The ideal solution for finished parts across industries, especially as design, furniture, arts and entertainment.

Dimensions (mm): 650x300x150

Weight (kg – lbs): 16 – 35.5

Nozzle (min. – max. mm): 1 – 5

Temperature (°C – °F): 350 – 662

A flexible solution for varying needs, this printing head covers a broad range of applications: from advanced end-use parts to design and architectural structures – achieving both details and high throughput.

Dimensions (mm): 1150x550x300

Weight (kg – lbs): 45 – 99

Nozzle (min. – max. mm): 2 – 8

Temperature (°C – °F): 450 – 842

A robust extruder, with a high throughput to guarantee best efficiency and printing quality. It’s the best solution for large tools, molds and construction applications, as well as boat hulls and large structures.

Dimensions (mm): 1500x550x350

Weight (kg – lbs): 75 – 165

Nozzle (min. – max. mm): 5 – 14

Temperature (°C – °F): 450 – 842

Caracol’s extruders are offered with several systems that ensure productivity and efficiency of the machine. This includes automatic feedstock of material with the drying and feeding systems, layer cooling unit, anti-collision system, as well as control on all aspects such as temperature, melt flow and extrusion speed.

For its industrial line extruders Caracol has developed an Automation and Control unit to achieve precise control and high flexibility. Manage both High Flexibility and High Flow extruders interchangeably, adapting your Heron AM platform to different applications. The extruders and process parameters can be managed seamlessly with a user-friendly HMI for quick side-machine operations. The centralized Control Unit is suitable for the use of multiple end-effectors through a plug-and-play logic.

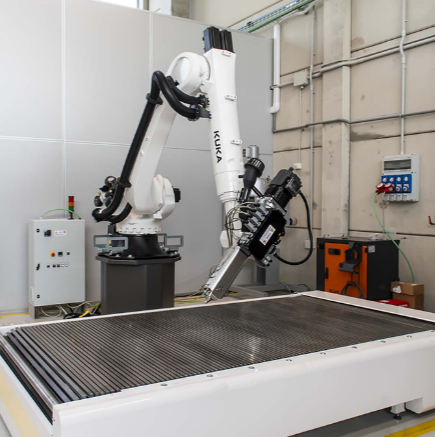

Leveraging the flexibility of the 6+ axes movements, robotic arms allow Heron AM to manufacture parts with very complex geometries, including non-planar tool paths, and unconventional slicing at different angles such as 45° or 60. Robotics also allows to modularly set up the system with different arm sizes to satisfy specific needs on applications or production area. Furthermore, arms can be extended on the x-axis with a rail or on the y-axis adding a plinth. To provide the best automation solution, Heron AM can be setup with robots from KUKA to FANUC and ABB.

Caracol developed its software platform Eidos Manufacturing, with years of experience in Design for LFAM, slicing strategies, and robotic cinematics. The software suite completes Heron AM’s hardware, ensuring full control and flexibility on the process.

With the 3D Path Planning Algorithms users easily set up the programming of complex tool paths in few steps, assuring maximum control also on the most challenging geometries, and on all production parameters.

With the IoT platform, it is possible to enhance the manufacturin process’ quality and repeatibility, starting from a data-driven approach that collects and analyzes data from every print.

The printing bed is key to successfully print parts. Caracol has developed several models to fit all needs, customizable in terms of size.

The aluminum frame structure with interchangeable top panels, is a convenient and flexible set up. With a simple brim or raft it ensures stability throughout the job. With the simple stainless-steel bed, high rigidity and planarity, anti-corrosion, and durability are guaranteed.

The patented automatic bed for unmanned part clamping and unloading was designed by Caracol to guarantee automated production with great part stability. The aluminum slats structure allows mechanical gripping of the first layer. Rotating at the end of each cycle and releasing the printed part autonomously, this printing bed is ideal for continuous production.

The direct and continuous supply of material is possible thanks to the automated material feeding system, developed by Caracol. A drying unit is connected to the extruder to input pellets during the whole printing cycle, avoiding manual operations that could stop the machine’s job.

Pellets and shreds are stored at the right humidity and temperature and dried for best performance and quality. Its capacity of 50-80 Kg (110-176 lb) can be extended with direct connection to a bigger storage or with multiple material feeding units, to facilitate production-continuity for unlimited hours.

Perimetral protections are key to ensure best printing conditions and safety. Enclosures allow to control environmental parameters, such as temperature and humidity, and track them to guarantee process repeatability and quality.

Customers can opt for different configurations: Structural Insulated Cells, for a completely enclosed and fully climatized environment suit manufacturing of high-temperature and high-performance composites, such as for aerospace components; Mobile Containers are ideal solution for in-situ manufacturing in remote locations such as construction and offshore sites, or camps set up during emergencies; when working with low-temperature materials Heron AM can operate open air, at the room temperature guaranteeing operators’ safety with Safety Light Curtains or with Protective Cages such as metal or plexiglass structures.